Fill Valve Wiring Diagram Ge

Exactly what is a wiring diagram.

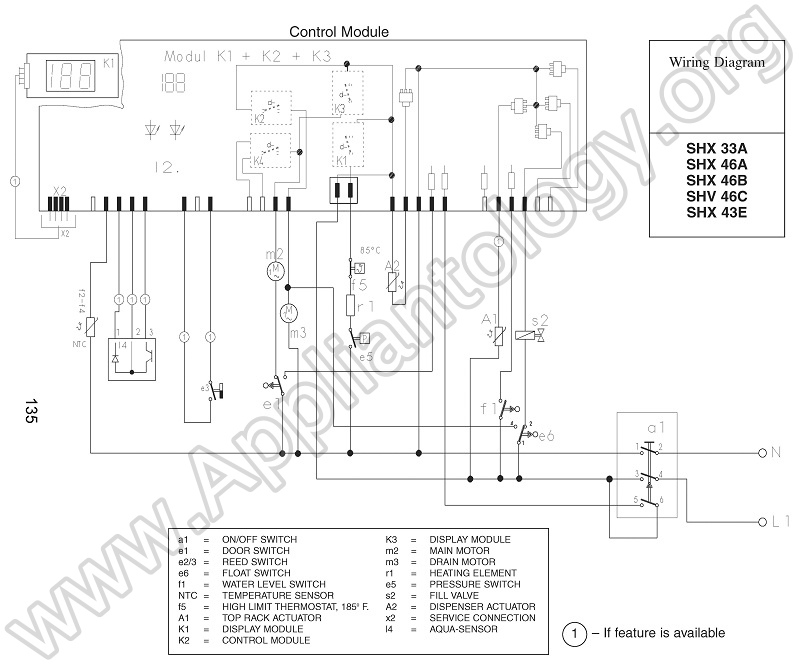

Fill valve wiring diagram ge. A wiring diagram mini manual schematic is packaged with each appliance. A wiring diagram is an easy graph of the physical connections as well as physical format of an electric system or circuit. Water valve assembly water valve assembly models 2xx 4xx models 6xx j514b j514 16 1374 1515 1374 1515 1515 1374 cold rinse fab soft cold models 6xx only j615 user interface board b 24 posi ve common n 24. Its purpose is to provide a method of supplying water for the wash and rinse cycles.

Schematics wiring diagrams cont schematics wiring diagrams cont. Use either a digital or an analog multimeter to check continuity good electrical current of the valve solenoid coils. The most common locations for the wiring diagram is listed by product line below. To check for an electrical failure access the water valve usually found at the bottom rear of the refrigerator.

Refrigerator wiring diagram location freezer wiring diagram location ice machine wiring diagram location. The diagram may be mailed or e mailed. You can reach us by dialing 1. Schematics wiring diagrams continued next page 67.

If you cannot locate your wiring diagram you can call the appliances answer center with your complete model number. There should be a wire that runs from the float over to the water valve. Step 4 test valve seal. When as well as ways to make use of a wiring.

It demonstrates how the electric cords are adjoined and could additionally show where fixtures and also components may be linked to the system. Hose from the fill funnel. The water valve can fail either electrically or mechanically. Even if the solenoid works the seal may be broken or the dishwasher inlet valve could be clogged with dirt and particle from the water supply line.

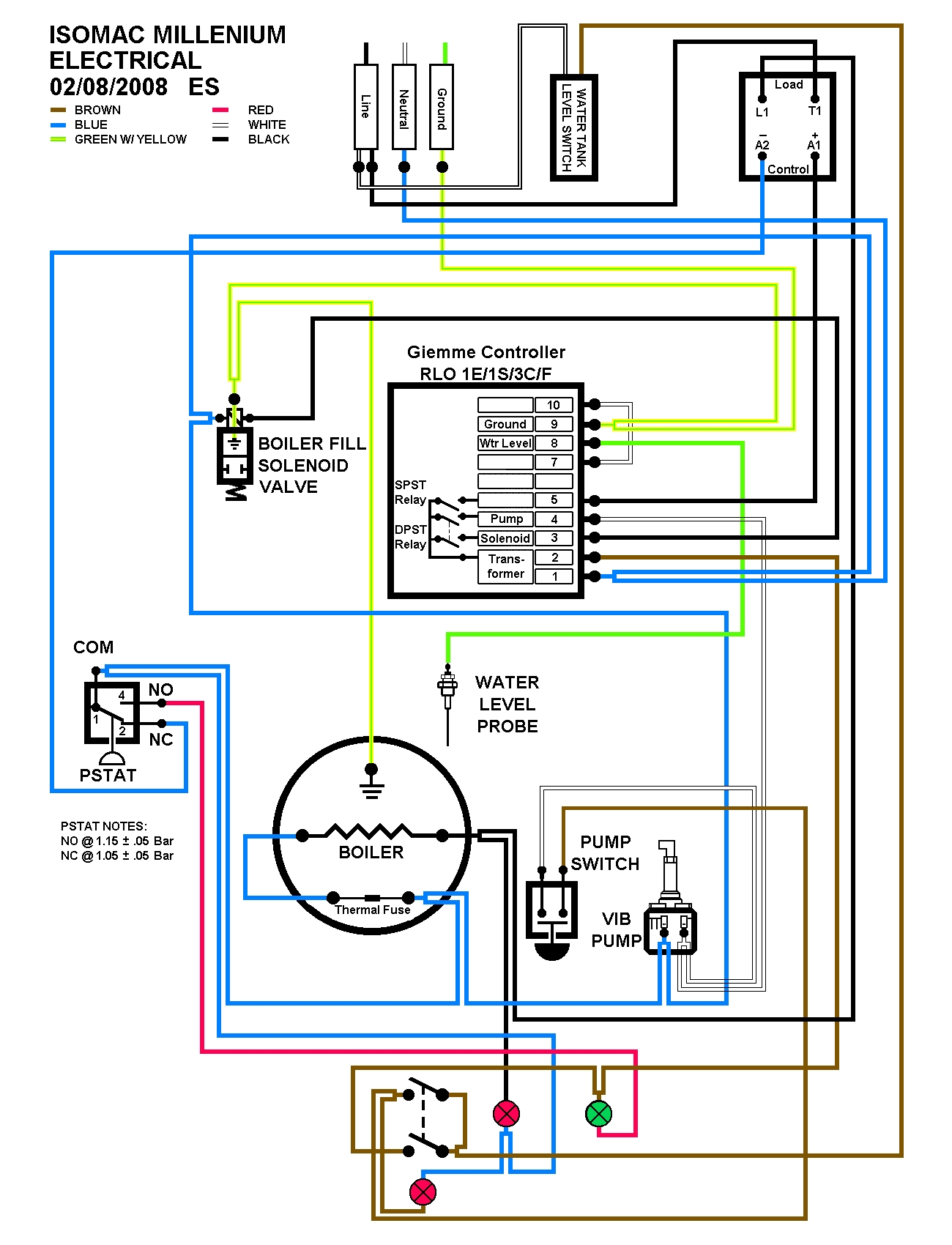

In a water fill valve the solenoid s actuator is attached to a diaphragm which opens or closes a route through which water can pass. You want to measure the other two. As soon as the water valve s solenoid coil is powered the armature allows the diaphragm to flex opening the passage and allowing water to flow. Remove the door s inner panel and check the wires visually and then for continuity.

Wiring diagrams of plc and dcs systems di do ai ao x liquid level control using flow loop control systems since liquid level can only change in a vessel if there is an imbalance of inlet and outlet flow rates would this system be practical to achieve stea. Loosen the clamp and disconnect the fill funnel shown with access panel removed. When not engaged the diaphragm is closed and no water should flow. A solenoid is simply an electromagnet.

Meter lead wire from control float switch wire water valve meter lead if no 120 then remove power from the unit. Unfasten the supply at the valve take out the screened washer inspect and clean it out and reinstall.